- Product

- Company

-

Solutions

By Use CaseBy Industry

- Partnership

-

Resources

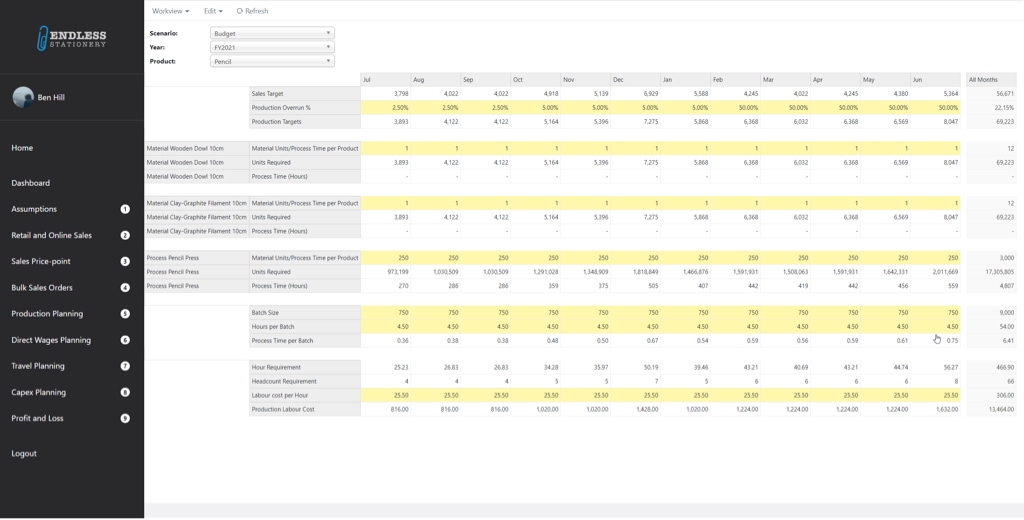

Ensure your BOM accurately reflects your forecasted production capacity and product demands

Production planning is a crucial tool for manufacturing organisations to ensure product demand is met and production capacity is actively managed. Implementing an effective production plan means organisations are able to model accurate production forecasts and follow the most efficient processes to produce products - from the initial product design to procurement to manufacturing. Furthermore, an effective production plan establishes a synergy between the needs of the customer and the organisation and works to optimise both customer-dependent processes, such as on-time delivery and customer-independent processes, such as production cycle time.

Key aspects of seamless production plans include:

Organisations still using traditional spreadsheet software for their production planning processes face numerous software limitations and leaves room for error. Moving to a cloud-based planning platform ensures that organisations can match production volume to product demand every time.

Integrate MRP planning with your operational planning to easily track and manage your production processes like demand forecasts, procurement, BOM costing, stock level analysis and capacity planning.

Optimise resource management with detailed drivers to model resource requirements around inventory, supply chain, product and staff. Utilise variance analysis at any level to gain a granular understanding of your product, BOM or production line.

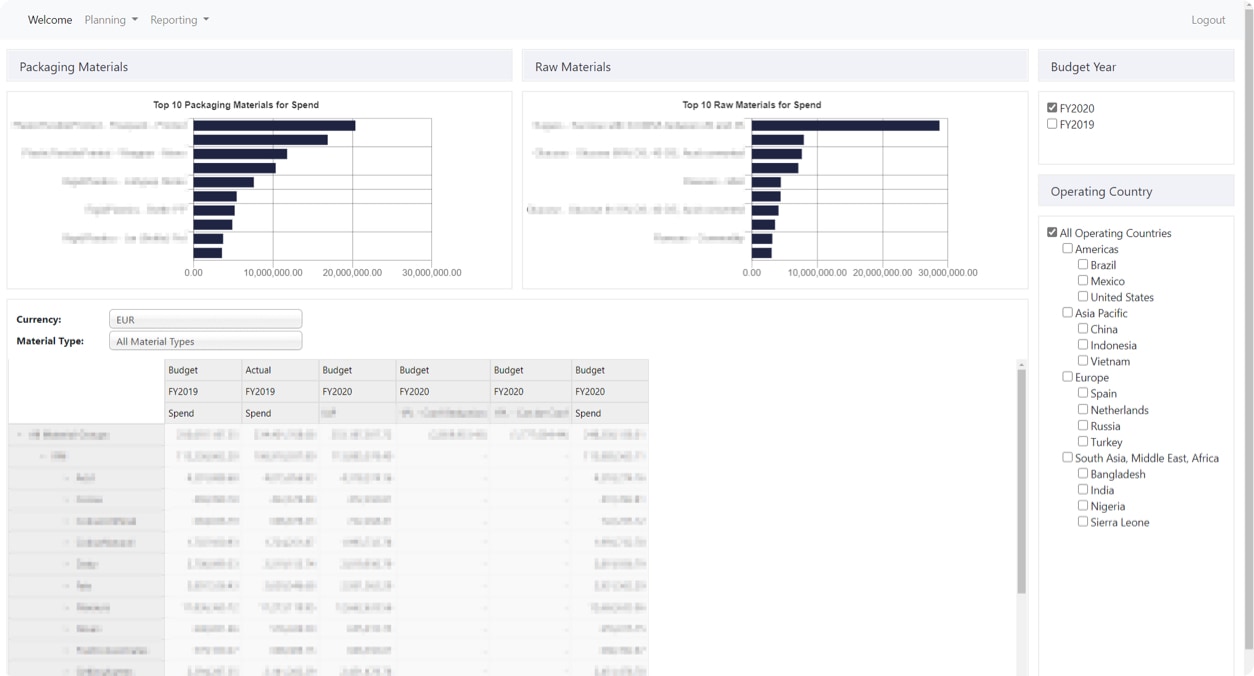

Gain a granular understanding of activity costs and their impacts on margins, with drill down of data relating to products, production line, SKU level or work order, and allocate direct, indirect and activity-based costs from there.

Plan for manufacturing sites in international locations and join your purchasing power to buy materials at competitive prices from global sources.

Collaborate in real-time with users from across the globe to ensure that all necessary logistics for materials and products are always accounted for.

Connect to your ERP to automatically pull the most recent actuals

Plan and Report on MODLR models from within Excel Workbooks.

View Audit reporting of who changed what, and when

Collect commentary on variances between actuals, budgets and forecasts

Apply business logic across models globally, not in fits and starts across specific cells in certain spreadsheets

Send emails or SMS alerts when submissions are made to the budget

Quantify the financial impact of your changing operational drivers

MODLR can adapt to different types of budgeting styles and methods, such as zero-based budgeting

Gain full confidence in your production processes, with comprehensive knowledge of the impact of changes to scheduled resources, available capacity and process times. Unify your plans and sales targets with one unified CPM solution and use real-time insights to ensure production schedules always meet product demand and staffing requirements, minimising bottlenecks and maximising profit margins.

Customise your production dashboards in MODLR to quickly examine the effects and feasibility of your production and capacity plans, alongside simulating different scenarios with raw material mixes, master schedules, job orders or production lines.

Watch this webinar which showcases MODLR's Production Planning Solution.

To see the MODLR Cloud in action, schedule a personal demo with one of our modelling experts or watch an overview of the cloud platform.

Get a demo